| MOQ | 50K–100K |

|---|---|

| Size | 50*70mm(Min) 350*600mm(Max) |

| Material | BOPP/PET+PET/PETAL/Kraft Paper/+LLDPE/CPP |

| Thickness | 50Mircons-120Mircons (2Mil-5Mil) |

| Function | Punch Hole, Handle, Metallized |

| Printing | D-Met Printing, Vanishing, Matte Finishing, Stamping |

| Products | Normal Material Use |

| Chips | BOPP/CPPAL,BOPP/PETAL/CPP |

| Noodles | BOPP/PE,PET/PE,BOPP/CPP |

| Candy | BOPP/CPP,PET/PE |

| Frozen Foods | BOPP/PE,BOPP/CPP |

| Industry | Products Use |

| Dry food | Snack bars, Nuts, Cookies, Biscuits, Macaron, Sandwich cake |

| Inflatable food | Potato chips, Potato crisps, Snack chips, Fried chips, Fried chicken bar |

| Confectionery | Jawbreaker, Gummy, Hard Candy, Lollipop, Chocolate bar, Gum, Rainbow Candy, Sandwich candy, Fruit powder sugar |

| Others | Noodles, Frozen dumplings, Pizza, Spices, Seafood |

Frozen Packaging Pouches

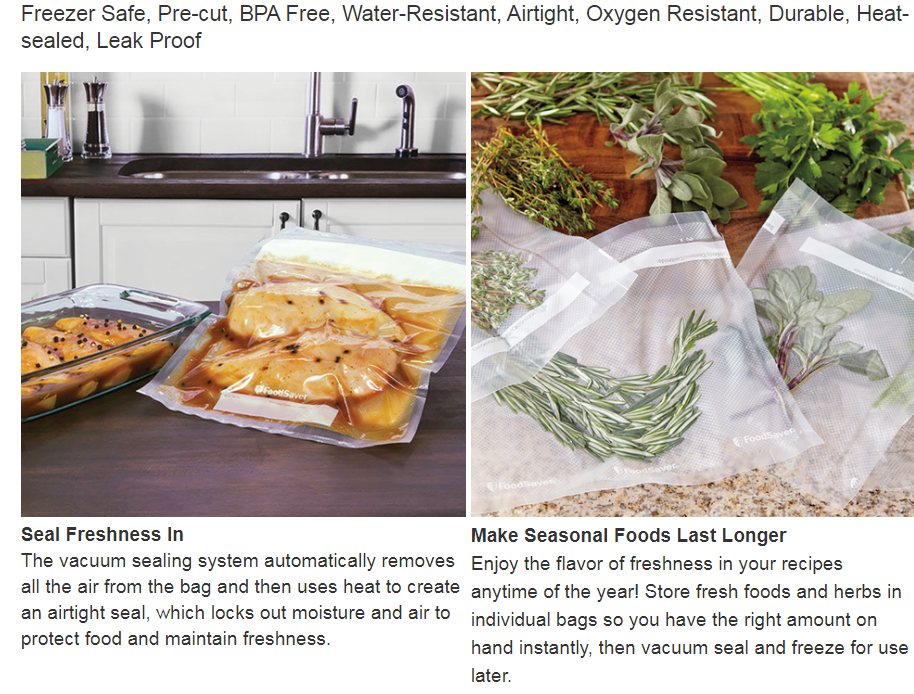

Frozen bags means that the packaging bag can effectively protect the contents from damage and keep the product fresh under low temperature. At the same time, the material structure of the packaging bag itself will not become brittle due to low temperature. It should have the function of anti puncture and tear resistance and high barrier。

Distinguish from bag’s shape: Fin seal frozen bags ; Fin seal gusset frozen bags ; Stand up frozen bags ; Flat bottom frozen pouches.

Distinguish from bag’s functionally: Vacuumized frozen bags and non- vacuumized frozen bags.

Distinguish from bag’s material: Transparent frozen bags, Aluminum foil frozen bags .

Frozen bags are widely used in perishable foods such as meat, poultry, aquatic products, dairy products, eggs, vegetables and fruits.

At LIBOPACK, frozen bags are very popular products, especially in European and American countries. Their frozen food supply chain is very mature and there is more and more demand for frozen bags. LIBOPACK ensures that all materials are food grade and BPA free .

Flexible packaging roll films

Fin seal pouch & bag

3 side seal pouch & bag

Gusset pouch & bag

Stand up bag & pouch

Shaped bag & pouch

Spout pouch & bag

Flat bottom bag & pouch

By the way. LIBOPACK has HP 20000 digital printing press, which can print plastic, paper and other materials, with a daily output of 50000-80000pcs.

Please contact us immediately, we will quote within 8 hours.

Different kind of styles pouch for choice :Stand up pouch with zipper /Quad seal Pouch with value /Middle seal Pouch/Auto-Packaging plastic roll film/Kraft paper aluminum foil pouch etc .

Frozen food is nutritious, convenient, hygienic, economical and easy to preserve for a long time. It is widely used in the production, transportation and storage of perishable food such as food, fruit and vegetables. Since frozen foods need to be stored at low temperatures, the packaging must be cryogenic and insulated from bacteria in the bag. It cannot be altered at sub-zero temperatures to ensure that food is not damaged during transportation and sale.

Frozen Packaging Pouches—-Frequently asked questions you are most concerned about:

1、What is a frozen bag?

Frozen bag is for packaging frozen food and non-food. It is stored, transported and sold at low temperature. The frozen bag material has the characteristics of low temperature resistance, puncture resistance and high barrier.

2、What are the characteristics of frozen bags?

Low temperature resistance: even at the low temperature of – 45 ℃, the material will not deform and embrittlement.

Oil resistance: the packaging materials do not absorb oil, and the fat components in the food can be completely retained to maintain the original taste of the food.

High barrier: prevent the food from deteriorating due to contact with oxygen. At the same time, prevent the moisture content in the food from exerting and retain the fresh taste of the food. And it can prevent toxic and harmful substances from penetrating into food.

High tensile strength: frozen food tends to become hard, and edges and corners will pierce the packaging bag. The packaging bag is required to have good impact resistance and puncture resistance, of which NY has the best tensile strength.

Safety and health: all materials are food grade and BPA free.

3、Frozen bags need to be vacuumed?

Such packaging depends on the product, such as packaging perishable meat, meat products, or rice, beans food, is generally to use vacuum packaging. In this way, the shelf life of food can be extended.

All vacuum packaging of frozen food, packaging materials must have puncture resistance and tear resistance.

4、The importance of frozen bags in daily life.

Frozen bags play an important role in the frozen food industry chain. First , the frozen bag materials has superior tensile strength, is not easy to be damaged and broken, and can protect the integrity of food; Secondly, the high barrier properties of the material ensures that toxic and harmful substances such as oxygen and bacteria come into contact with food; The most obvious feature is the low temperature resistance of the material, which can keep food fresh for a long time and facilitate long-distance transportation and storage.

5、What materials does the frozen bag consist of?

5.1. At low temperature of 0 ℃ – 4 ℃: OPP / PE, PET / LLDPE.

5.2. Between 0 ℃ and – 45 ℃: PET / LLDPE, NY / PE.

5.3. If high barrier materials that can block light are required: PET / Al / PE, NY / Al / PE.

5.4. Vacuum freezing bag: NY / PE.

5.5. High temperature retort and freezing bag: NY / RCPP, NY / Al / RCPP, PET / Al / NY / RCPP.

6、Can frozen bags be packed automatically?

Certainly. Because the food will become hard after freezing and will not adhere to each other, it is convenient to use the automatic packaging machine for packaging, which ensures food hygiene and is economical.

7、Is the material of the frozen bags safe and hygienic?

Please don’t worry. that the materials are food grade and BPA free. LIBOPACK ensures that the production and storage of packaging bags comply with food safety standards, and can also provide corresponding test reports according to customer requirements.

8、Can the material of the freezing bag be recycled?

Certainly. The materials used are safe, reliable and easy to recycle.

9、Can freezer bags be reused?

Based on health and safety considerations, we do not recommend repeated use, because long-term use of frozen bags may produce bacteria and other harmful substances, so the used frozen bags should be garbage classification, recycling and reuse.

At the same time, the long-term use of frozen bags, material’s barrier is greatly reduced, has been unable to meet the requirements of food preservation.

10、Can we get a free sample?

Of course, LIBOPACK has a long stock of freezer bags. If you need to confirm samples, please contact our sales staff directly.

*

Chapter 1.

Conclusion

The frozen bags has a wide range of uses. It can be used in the food industry and is also an essential thing in family life. It ensures that the food will not be damaged, deteriorated, hygienic and nutritious in the process of production, transportation, storage and sales.

LIBOPACK has many years of professional knowledge and skills in producing frozen bags. I believe we will become a good helper in your business and life.

LIBO Packaging

√Professional team both in production and R&D .

√ The excellent high quality Standing zipper plastic bag food packaging bag supplier in the world.

√ The largest high quality non-adhesive tape supplier in the world.

√ Sound capital foundation, international advanced management system.

√ Professional packaging supplier and quick response, delivery on time.

√ Innovative ,Pragmatic, Collaborative development conducting philosophy, Built solid base for LIBO of leaping future.

Professional production: Auto-packaging Plastic film ,Compound packing bag, Plastic roll film, Kraft paper Pouch,Vacuum bag, Aluminum foil bag, Spout pouch and Shape bag etc.

If you are interesting our company new products catalog also .Please help to contact with us soon !!!

(24*7 After Sales Services) Then We will offer more competitive products price for you in time .

Three sided seal frozen bags for fish

Three sided seal frozen bags for fish ,This is not an ordinary frozen bag, because in the frozen state, the fish’s body will become hard and have strong damage to the packaging bag. It is required that the packaging material should not only have high barrier, but also have the ability of puncture and tear resistance to ensure the safety of the product in the process of transportation and storage.

Three sided seal frozen bags for seafood

Three sided seal frozen bags for seafood , The packaging bag is required to have low-temperature properties, which will not affect the strength after lamination, and ensure that the material will not be brittle and has certain flexibility. Therefore, we often choose to use NY / LLDPE, food grade material and BPA free.

Three sided seal frozen fish bags

Three sided seal frozen fish bags , The materials are required to have high barrier to prevent food moisture loss, fat oxidation and reduces freezer burn, which affect the freshness and unique taste of food. Therefore, NY / PE is often used in LIBOPACK, which can perfectly solve this problem.

Fin seal frozen bags for dumpling

Fin seal frozen bags for dumpling , Before packing, the dumplings quickly frozen at – 30 ℃ to – 40 ℃ within 30 minutes will become hard and have a certain puncture force. Therefore, the packaging materials must have the ability of puncture and tear resistance. Generally, PET / LLDPE and NY / LLDPE are used.

Fin seal window frozen bags for food

Fin seal window frozen bags for food, We may complete it through the automatic packaging machine. After frozen, the food is sorted and weighed by the automatic packaging machine, packaged with flexible packaging film, and then refrigerated.

The transparent window can clearly show the preservation of food.

Three sided seal window frozen bags for wheaten food

Three sided seal window frozen bags for wheaten food , Before packing, the food shall be quickly-frozen at – 30 ℃ to – 40 ℃ and then refrigerated. The packaging bag material must have good barrier to prevent the food from contacting with oxygen and water volatilization, prolong the shelf life of the food and ensure the fresh taste of the food.

Three sided seal frozen bags for food

Three sided seal bags for food , Packaging materials have high barrier, good oil resistance, and can block the entry of external oxygen, prolong the shelf life of food, and retain the moisture content and fresh taste of food.

Food grade materials and BPA free, can be safely used.

Three sided seal frozen fish bags

Three sided seal frozen fish bags , The food is packaged immediately after quickly-freezing, which can effectively ensure that the moisture content in the food is not volatile. Then, under the -45℃low temperature state, the materials used in the packaging bag are required not to be deformed and brittle. At the same time, it is necessary to prevent the migration and penetration of toxic and harmful substances into the food.

Fin seal gusset frozen food bags

Fin seal gusset frozen food bags , PET / LLDPE and NY / LLDPE are usually used. The material has high barrier. After the lamination process, the structural strength of the material can be greatly improved. LLDPE has good low-temperature heat sealing properties to ensure that the packaging bag is not broken, safe and reliable.

Fin seal gusset frozen bags for wheaten food

Fin seal gusset frozen bags for wheaten food , The material structure is basically PET / PE and OPP / PE. There is a plastic food tray in the packaging bag, which can reduce the damage of external pressure on food during transportation and refrigeration and ensure the integrity and beauty of food.

Three sided seal frozen pouch for food

Three sided seal frozen pouch for food , As shown in the figure, the food is in the shape of a ball. Even after freezing, it will not puncture the packaging bag. Therefore, in order to save packaging cost, PET / PE and OPP / PE are the best choices.

Food grade materials, BPA free, can be safely used.

Three sided seal retort pouches for frozen pet food

Three sided seal retort pouches for frozen pet food

Three sided seal retort pouches for frozen pet food , If the meat products eaten by pets need to be stored and transported for a long time, they must use high barrier and 121℃- 135 ℃retort packaging materials. At the same time, the materials need to be resistant to low temperature and oil. The high barrier properties of the materials can prevent the pollution of bacteria and harmful substances to food.

Material structure of this kind of packing bag: PET / Al / NY / RCPP.

Three sided seal frozen meat bags

Three sided seal frozen meat bags , Packaging materials must have low temperature resistance and high barrier properties, so as to ensure that meat products will not deteriorate under the influence of external oxygen, and the moisture content and nutrition of meat products will not be lost, so as to retain the original taste.

Three sided seal frozen pouches for meat food

Three sided seal frozen pouches for meat food , Material structure: NY / RCPP, high barrier material, can withstand 121℃- 135 ℃ high-temperature retort and sterilization, and then refrigerate at low temperature, which can effectively lock the moisture and fresh taste and prolong the shelf life of food.

Three sided seal frozen bags with vacuum

Three sided seal frozen bags with vacuum , It is required that the packaging materials must be suitable for vacuumized and refrigeration. The purpose of vacuumized is to discharge the air inside the packaging bag, avoid food oxidation and prolong the shelf life. At the same time, after the food is frozen, the packaging bag must have the ability to resist puncture and tear.

LIBOPACK usually uses NY / RCPP to solve this problem.

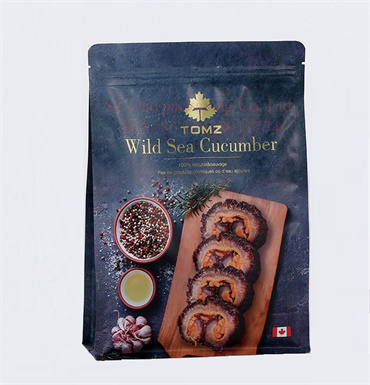

Aluminum stand up frozen bags

Aluminum stand up frozen bags , Due to the use of metal aluminum, the barrier performance is improved, which can effectively prevent the entry of moisture and oxygen and prolong the shelf life of food. It is often used to package milk candy, dried fruits and meat products, because these foods need to be refrigerated. Food grade materials and BPA free .

Stand up frozen fruit bags with zipper

Stand up frozen fruit bags with zipper , The packaging materials are with aluminum film, which greatly improves the barrier and can effectively against moisture, oxygen and UV lights. If yogurt is packaged, it only needs to be placed in the refrigerator and stored at 0 ℃ – 4 ℃.

Transparent stand up frozen pouches with zipper

Transparent stand up frozen pouches with zipper , This kind of frozen bags does not need to have too many functions. It only needs to ensure the high barrier properties of the material to prevent moisture and oxygen, and then put it into the 0 ℃ – 4 ℃ cold storage room.

The zipper can be closed repeatedly for easy use.

Stand up frozen pouches for seafood

Stand up frozen pouches for seafood , They are often placed on the shelves of shopping malls for refrigeration to show consumers the storage of food. Reusable zippers facilitate consumers to close in time after opening, and then put them into the refrigerator for refrigeration.

Three sided seal vacuum bags for frozen food

Three sided seal vacuum bags for frozen food , The NY/PE material has high barrier properties, locks out moisture and air, and is resistant to oil and low temperature storage conditions. After vacuuming, the internal air can be discharged, extending food shelf life and saving storage space.

Window stand up frozen bags with handle

Window stand up frozen bags with handle , Food grade materials, BPA free, even in the -45 ℃ low temperature will not deformation, not brittle, at the same time, can prevent toxic, harmful substances migration into the food. The material is resistant to oil and can effectively preserve the fat and protein in food.

The use of Handle is convenient for consumers to carry.

Clear flat bottom frozen pouches for food

Clear flat bottom frozen pouches for food , It is generally composed of two layers of materials, PET / PE and OPP / CPP, which are stored at the temperature of 0 ℃ – 4 ℃. The packaging materials have good barrier property, which can prevent the loss of food moisture and maintain the softness of food. The materials used are food grade and BPA free.

Aluminum flat bottom frozen bags for seafood

Aluminum flat bottom frozen bags for seafood ,Aluminum has superior barrier properties. After laminating with other materials, it can maximally block the impact of external moisture, oxygen and UV lights on food. At the same time, it can lock the moisture inside the packaging bag, ensure the freshness and taste of food, and prolong the shelf life of food.

Aluminized film flat bottom frozen pouches for dumpling

Aluminized film flat bottom frozen pouches for dumpling , The materials used are oil-resistant, the nutrients in the food will not be lost, and have high barrier, keep the moisture of the food, and the food will not become dry and brittle. At the same time, the high barrier materials ensure that toxic and harmful substances cannot penetrate and migrate into the food.